Process Validation & Tooling

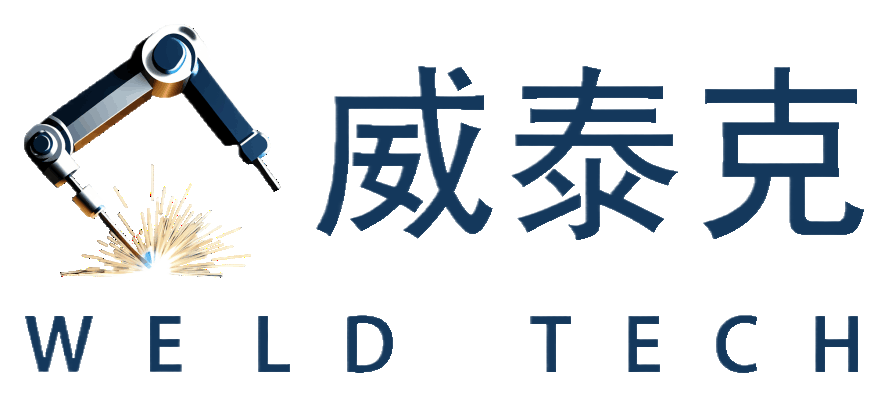

We design and manufacture all welding fixtures and production tooling in-house.

Each tool is validated by performing a full dimensional inspection on first-off samples.

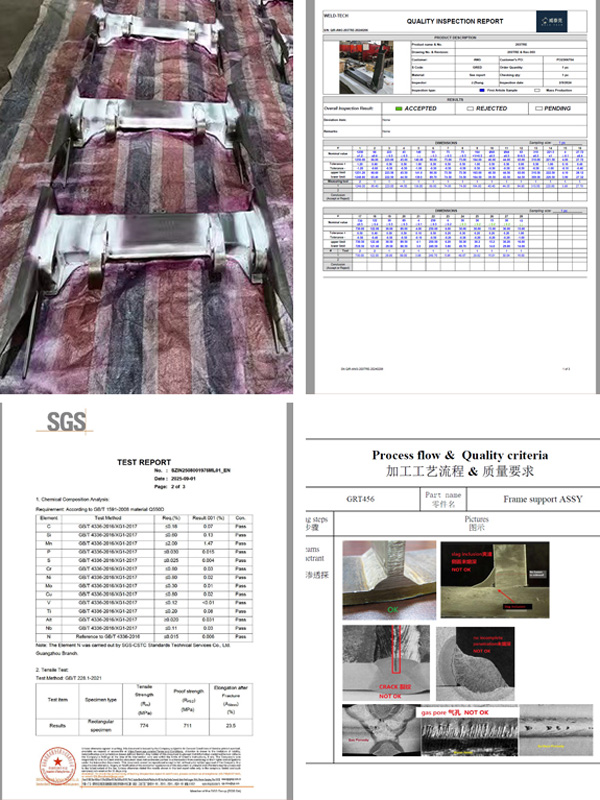

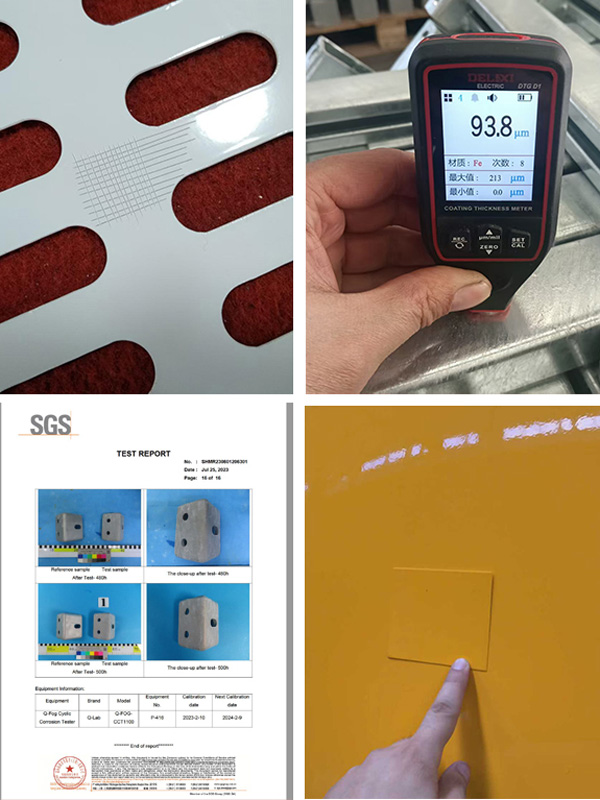

For all critical dimensions, we produce custom checking gauges to guarantee precision and consistency throughout the manufacturing run.